Stay Connected...Drop Us a Line

For best user-experience, hit 'TAB' to move from field to field.

Cleaning Basics...Part 11

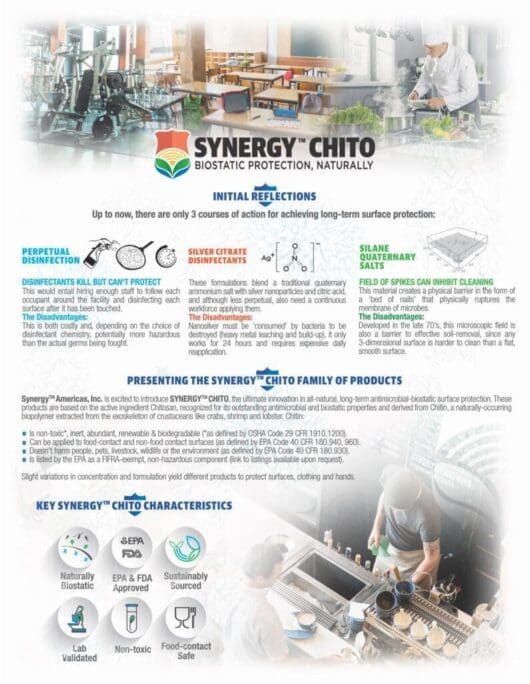

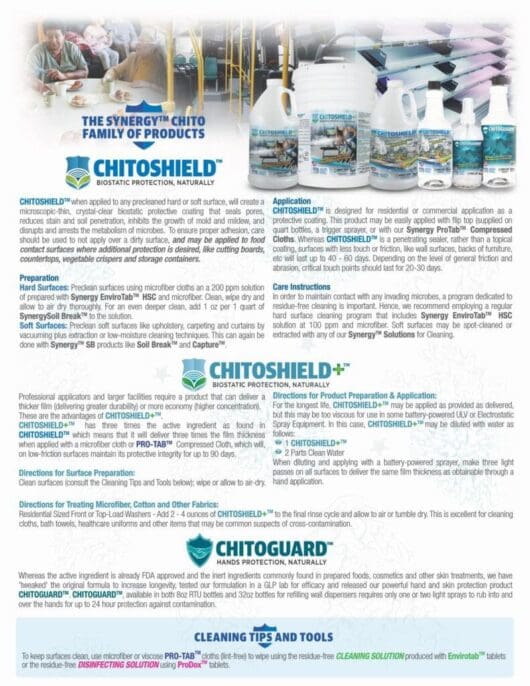

Why Antimicrobial Protection is Essential

Listen to the Audio Version:

This frantic preoccupation with disinfection is illogical.

Think about it. 'Registered' disinfectants are tested and certified microbial pesticides, meaning that they are proven to have the capacity to kill bacteria, fungi and viruses within a given period of time - usually within 10 minutes. Many of these pesticide labels insist that after that period they be rinsed with potable water. Do you know why? It is because they contain toxic or at least harmful ingredients that must be rinsed away or they will be detrimental to the occupants of the spaces in which they have been used.

These classes of such disinfectants are called quaternaries and phenolics, and they still account for too high a percentage of all disinfectants used. Cleaners and housekeepers don't have the time to wait the prescribed period to remove the residue, so there it sits, on the tables where children eat their lunches, on the toys toddlers put in their mouths and on the surfaces so many people touch ahead of rubbing their eyes, wiping their mouth or scratching their nose. The industry is poisoning the population.

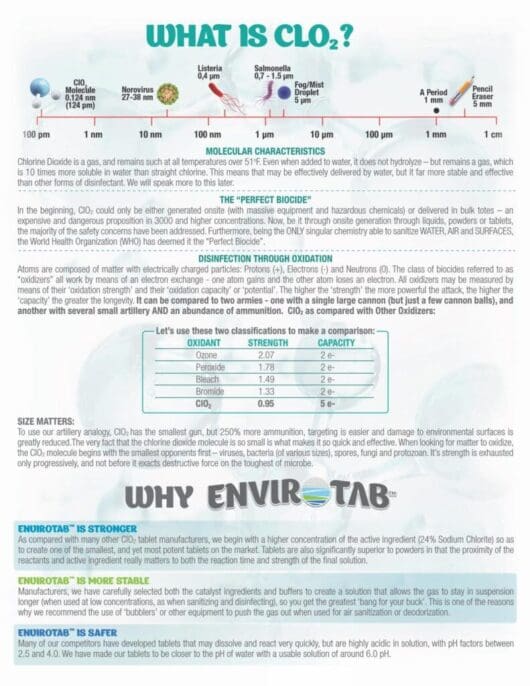

The other common class of disinfectants are called oxidizers, and they are not nearly as toxic or hazardous, and in most cases these do not leave any residue, but they also have no lasting effect. These are the peroxides, hypochlorous acids and chlorine dioxide products.

So, let's crunch some numbers...

Let's say that the first two classes are used as prescribed: applied and removed after 10 minutes with clear, clean water. Or the oxidizer is applied, and requiring no rinsing burns off into the air and is gone. Either way you have a window of purity, an assurance of sanitization of just 10 minutes.

The first infected person to touch, breathe or otherwise deposit bacteria on the previously disinfected surface will ruin it for the other 99.94% of the day.

What is needed is a non-toxic means of protecting the surfaces people touch around the clock and for days on end. Protecting the surfaces will protect the people, it's really that simple. And as you will see in the segment to follow, the concept of antimicrobial protection is nothing new, with many metals having been recognized millennia ago for their germ control and anti-spoilage properties.